How to choose a best LED high bay light?

1. Look at the material and type of the heat sink. Generally speaking, the higher the purity of the aluminum material, the larger the area of the heat sink, and the better the heat dissipation effect. The LED high bay light with poor heat dissipation has a short working time, and a lot of heat energy will be generated within a few hours, and the heat that cannot be dissipated will continue to affect the life of other accessories such as lamp beads.

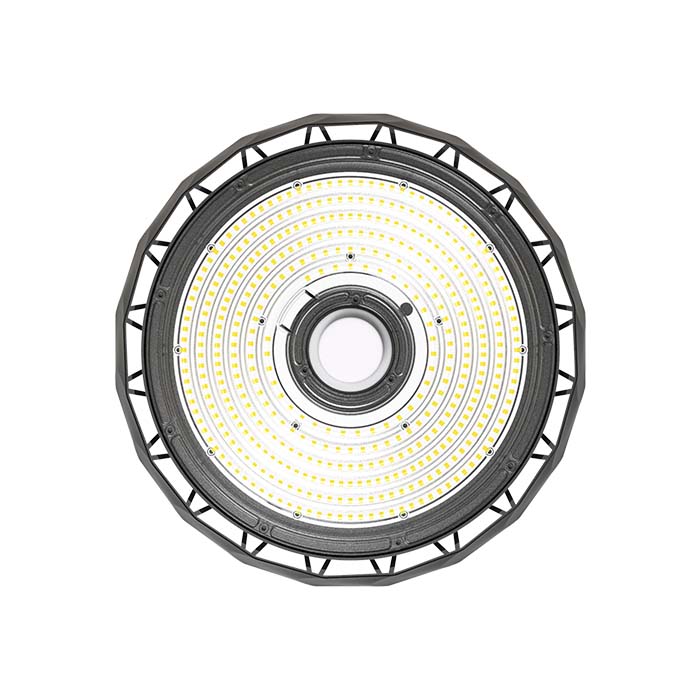

2. Look at the lamp bead chip. The lamp bead chip affects the quality of the product. A good lamp bead chip can make the led high bay light work stably for a long time, with lower light decay and longer service life.

3. Looking at the power supply, LED high bay lights are energy-saving products, and the power of the driving power supply should be high. Regarding the structure of the LED high bay power supply device in the lamp, because the luminous power of the LED decreases with the increase of the LED temperature, the heat dissipation of the LED is very important. The power of the power supply is high, its power consumption is small, and the heat generated in the LED high bay light is small, which is more beneficial to delay the light decay of the LED high bay light. The life of the power supply directly affects the life of the entire lamp.

4. Looking at the power, there are often manufacturers on the market that use 80W to falsely mark 100W or even higher LED high bay lights. Of course, buyers can't see it, but they only need to be connected by an electric energy meter or checked by a power meter to see their practice. power. The virtual standard power directly leads to poor illuminance, so the actual lighting quality cannot meet the requirements.

5. Looking at the lens, there are generally several types of lenses, and the functions are different. You can choose according to your own needs, please see the following:

Silicone material

Now the silicone material LED high bay light manufacturer shell kit lens is a more widely used one in the market. Relatively speaking, it has ultra-high light transmittance, small size and good heat resistance. It can also be reflow soldered. , so it can be widely used in led packaging operations.

PC material

The LED high bay light lens of PC material is easy to be molded by injection molding, and the standard and control cost are relatively low, the strength is relatively good, and the light transmittance is slightly weaker than that of silicone material and acrylic material, but its high temperature resistance is far better than that of acrylic. The lens of the material is better.

Acrylic PMMA material

Acrylic pmc material LED high bay light manufacturer shell kit lens, generally used for high-power wall washer, its main feature is that the light transmission function is better, but compared with the silicone material lens, its temperature resistance function is slightly weaker , so the operating temperature is not easy to exceed 80 ℃.

Glass material--tempered glass

We generally use tempered glass during production. Near the IDLED high bay light lens, there is very little glass material. Because the lens of glass material is relatively expensive and has a higher light transmittance, but glass is a fragile material, so the market Glass lure mirrors are rarely used as lure mirrors for LED high bay light manufacturers’ shell kits.