Which material is better for LED high bay light lens?

With the advantages of energy saving, environmental protection, long service life and good color rendering, LED high bay lights are suitable for warehouses, supermarkets, large workshops, steel plants and manufacturing plants where high space lighting is required.

1. Silicone material: At present, the LED high bay light housing kit lens made of silicone material is widely used in the market. It has high light transmittance, small size and good heat resistance. It can be widely used in LED packaging operations through reflow soldering. .

2. PC material: The LED high bay light lens of PC material is easily molded by injection molding, and the standard and control cost are relatively low, and the strength is relatively good. Although the light transmittance is slightly weaker than that of silicone material and acrylic material, its high temperature resistance function Far better than acrylic lenses.

3. Acrylic PMMA material: The lens of the LED high bay light housing kit made of acrylic PMMA material is usually a high-power wall washer. Weak, the operating temperature should not exceed 80 ℃.

Advantages of LED high bay lights:

1. Using phase change heat dissipation technology, it has high stability, high reliability, high thermal conductivity, and heat transfer up to 340m/S.

2. Integrated design of heat conduction and heat dissipation, there is no risk of shedding, corrosion and leakage, the inner cavity of the working state presents negative pressure, there is no risk of expansion, and it is safe to use.

3. There will be no discharge of toxic and harmful substances in either the manufacturing process or the use process, which meets environmental protection standards.

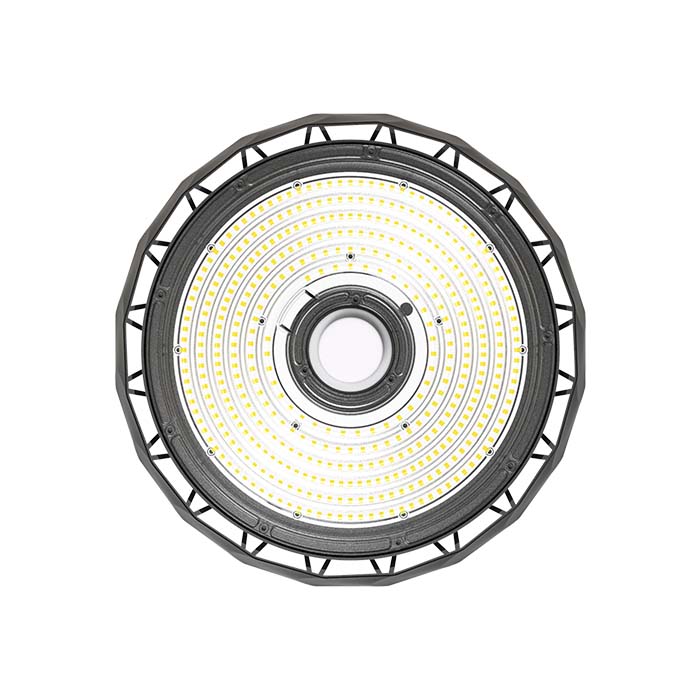

LED high bay light adopts LED plane integrated light source, which has small thermal resistance and low temperature rise. The lamp shell is part of the radiator and can directly conduct heat. Using a wide voltage design, the total power of the lamp body is basically unchanged when the voltage fluctuates, avoiding the stroboscopic situation and ensuring the stability of the lighting environment for workers. Because the LED plane integrated light source is used, there is no polluting material and ultraviolet and infrared radiation.

LED high bay installation method:

LED high bay light is a very important industrial lighting fixture. Its equipment method is flexible, the illumination intensity is strong, and the illumination intensity planning is wide, which is loved by many manufacturers. There are three types of installation methods: sidewall type, hanging type and mobile type.

1. Sidewall type: LED high bay lights installed on the sidewall are suitable for some light industrial workshops. This type of workshop is relatively low in height, light in work content, and requires relatively high contrast. It belongs to fine industrial lighting and uses sidewall installation. It can save energy and meet large lighting requirements with less illuminance.

2. Suspended type: suitable for heavy machinery production workshop lighting, this type of workshop lighting, the height of the workshop is very high, the required lighting planning is wide, the contrast requirements are not very high, compared with fine lighting, the difference is large, so it is suitable for hanging type .

3. Mobile: LED high bay lights are very special in mobile applications. They are used in outdoor factory and mine lighting environments. Due to outdoor lighting, especially in some places with very harsh environments, the input of electricity is difficult, and mobile LED high bay lights can be used in In this environment, the lighting requirements of the ambition are reached.