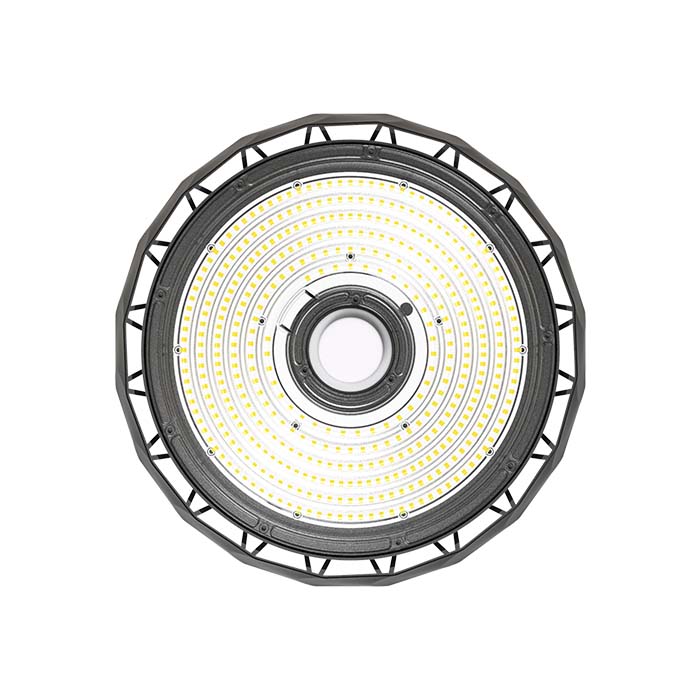

LED high bay light is a general term for lamps used in factories, mines, warehouses, high-rise buildings and other production places. In addition to the various lighting lamps commonly used in the environment, there are also explosion-proof lamps and anti-corrosion lamps.

According to the bright function, it can be divided into general lighting and local lighting. General lighting General lighting is generally evenly arranged above the workplace or on the side walls to illuminate the entire face. It requires the use of more powerful incandescent lamps, halogen lamps, high-intensity gas discharge lamps or a large number of fluorescent lamps. Of course, there are more energy-saving large lamps. Power LED high bay lights, etc., most high bay lights are like this. General lighting has higher requirements for light distribution, and two light distribution methods, direct and semi-direct, are widely used, especially the latter. Part of the semi-direct light illuminates the ceiling and increases the brightness of the ceiling, creating a more comfortable and brighter environment. Local lighting Local lighting is a kind of work to improve the illuminance of lamps and lanterns. Its function can strengthen and increase lighting on the basis of general lighting, and it can be used as temporary lighting in some places that do not need lighting at ordinary times (such as equipment maintenance and repair places). Most of their light distribution is not strictly regulated. Local lighting is usually installed near the work area, using incandescent lamps and halogen lamps with safety extra-low voltage (≤50V, AC rms) as the light source. There are (portable) line lights, chandeliers, table lamps, machine working lights, etc. In some high-rise buildings, projected light is sometimes used for local lighting. According to the light source, high bay lights can be divided into traditional light sources (such as sodium lamps, mercury lamps, etc.) and LED high bay lights. LED high bay lights have great advantages over traditional high bay lights: 1 LED high bay lights refer to RA>702 LED high bay lights are more efficient and more energy-saving, equivalent to 100W LED high bay lights can replace traditional 250W traditional high bay lights. 3 Traditional light sources have The shortcomings of high-temperature lamps, the lighting temperature can reach 200-300 degrees. LED itself is a cold light source, low-temperature lamps are safer, and they are all cold-driven. 4 LED high bay lights are constantly innovating, the latest fin-type radiator high bay light radiator design is more reasonable, greatly reducing the weight of the high bay light, so that the overall weight of the 80W LED high bay light is reduced to below 4KG, which perfectly solves the heat dissipation of the 80-300W LED high bay light problem. 1 LED high bay light refers to high RA>702 LED high bay light efficiency, more energy-saving, equivalent to 100W LED high bay light can replace the traditional 250W traditional high bay light. 3 Traditional light sources have the shortcomings of high-temperature lamps, and the lighting temperature can reach 200-300 degrees. LED itself is a cold light source, low-temperature lamps are safer, and they are all cold-driven. 4 LED high bay lights are constantly innovating, the latest fin-type radiator high bay light radiator design is more reasonable, greatly reducing the weight of the high bay light, so that the overall weight of the 80W LED high bay light is reduced to below 4KG, which perfectly solves the heat dissipation of the 80-300W LED high bay light problem. 1 LED high bay light refers to high RA>702 LED high bay light efficiency, more energy-saving, equivalent to 100W LED high bay light can replace the traditional 250W traditional high bay light. 3 Traditional light sources have the shortcomings of high-temperature lamps, and the lighting temperature can reach 200-300 degrees. LED itself is a cold light source, low-temperature lamps are safer, and they are all cold-driven. 4 LED high bay lights are constantly innovating, the latest fin-type radiator high bay light radiator design is more reasonable, greatly reducing the weight of the high bay light, so that the overall weight of the 80W LED high bay light is reduced to below 4KG, which perfectly solves the heat dissipation of the 80-300W LED high bay light problem. Equivalent to 100W LED high bay light can replace the traditional 250W traditional high bay light. 3 Traditional light sources have the shortcomings of high-temperature lamps, and the lighting temperature can reach 200-300 degrees. LED itself is a cold light source, low-temperature lamps are safer, and they are all cold-driven. 4 LED high bay lights are constantly innovating, the latest fin-type radiator high bay light radiator design is more reasonable, greatly reducing the weight of the high bay light, so that the overall weight of the 80W LED high bay light is reduced to below 4KG, which perfectly solves the heat dissipation of the 80-300W LED high bay light problem. Equivalent to 100W LED high bay light can replace the traditional 250W traditional high bay light. 3 Traditional light sources have the shortcomings of high-temperature lamps, and the lighting temperature can reach 200-300 degrees. LED itself is a cold light source, low-temperature lamps are safer, and they are all cold-driven. 4 LED high bay lights are constantly innovating, the latest fin-type radiator high bay light radiator design is more reasonable, greatly reducing the weight of the high bay light, so that the overall weight of the 80W LED high bay light is reduced to below 4KG, which perfectly solves the heat dissipation of the 80-300W LED high bay light problem.

LED high bay light application requirements

In order to meet the visual needs of different production operations and lighting installation conditions, the reflector of the LED high bay light should be able to produce a wide range of light distribution. The surface is painted and glazed into white, and the reflector made of aluminum, glass mirror, prism glass and other materials can obtain a wide light distribution. It is suitable for large-area, vertical or nearly vertical workplaces. It is suitable for high-rise buildings and Where a stand-alone device is required, reflectors made of prism glass, mirror glass, and polished aluminum can be used to obtain a narrow beam distribution.

Long-term reliable operation under harsh environmental conditions such as dust and humidity, LED high bay lights have special requirements in terms of structural design, housing and reflector. Enclosed lighting or uplift convection lamps should be used in dusty environments (see figure); in humid environments, attention should be paid to the enclosure of the enclosure and the surface treatment of the reflector; the common open-air lighting in the room uses an enamel surface reflective aluminum reflector with an oxide film The surface is thicker or coated with oxide film; considering the inevitable vibration at the production site, a fixed light source should be used for the release of the lamp holder.

There are many ways to fix it. Generally, the lamp has the form of ceiling, embedded, hoisting (using straight pipe or chain) and suction wall. Movable local lighting is equipped with corresponding hooks, handles, clips, etc.; fixed local lighting is generally fixed on the working machine with screws or fixing mechanisms.