Installation steps of LED high bay light:

1. Set the hook in advance at the position to be installed. It should be noted that the hook should be used in conjunction with the ring, and the load-bearing capacity should be paid attention to.

2. Clip the ring on the LED high bay light into the set hook, and hoist the lamp through the ring;

3. Connect the power cord from the site to the power cord of the lamp, then connect the cord, and do a waterproof and insulating treatment;

4. After turning on the power, observe whether the LED high bay light can work normally. After confirming that the light is on, the installation is completed.

LED high bay light aging before installation

Aging method 1: Multiple lamps are aging in series (constant voltage aging circuit, constant current aging circuit). This kind of LED high bay light aging method will affect the working current parameters of other LED high bay lights as long as one high bay light has a quality failure.

Aging method two: multiple lamps are aging in parallel. With this LED high bay lamp aging method, any change in the characteristics of a high bay lamp will not affect the aging parameters of other LED high bay lights.

Aging method three: multiple lights in series and parallel aging (series and parallel constant voltage aging, serial and parallel constant current aging). This kind of LED high bay lamp aging method will affect the working current parameters of other LED high bay lights as long as one of them has a quality failure.

Aging mode four: single constant current aging. This kind of LED high bay lamp aging method captures the current characteristics, this method is more scientific.

Installation requirements of LED industrial and mining lamps

1. First, check the integrity of the LED high bay light and complete accessories.

2. When installing or replacing LED high bay lights, turn off the power first. When connecting the power supply, pay attention to whether the input voltage is suitable. After the power cord is connected, be sure to do the corresponding waterproof and insulation treatments.

3. The wires on the LED industrial and mining lamps can be passed through the drilled holes and the wires behind the lamps can be fixed with wire clips to ensure firmness.

4. Pay attention to the length of the power cord of the lamp, and the connection of the lamp should be as long as possible, and the connection should not be knotted. Pay attention to distinguish the output connection, and do not confuse it with other lamps.

5. When installing the LED high bay light, please handle it gently, and don't drop it randomly and cause damage to the light.

6. If the external power line and signal line of the lamp are damaged, the power supply must be cut off first and the qualified engineering and technical personnel should repair or replace it;

7. The power supply and lamp beads used by LED high bay lights must be replaced and installed by professionals;

8. After installation, check the place to see if there are any blind spots in the lighting, and you should ensure that the lighting meets the requirements.

What are the characteristics of LED high bay light power supply

1. The LED high bay light power supply has high luminous efficiency, luminous efficiency is above 100 lm/W, and it should be better with the advancement of technology. The efficiency of LED high bay lights mainly refers to the effective light effect, which emits at 120 degrees, but it is still sufficient in most cases.

2. The power efficiency of LED high bay light power supply is high. Compared with ordinary lamps, it can save more than half of the electricity. LED high bay lights are generally used for lighting in factories and workshops. The number of lamps is relatively large, and the power-saving function is still very important.

3. The lifespan of LED high bay light power supply can reach 50,000 hours. It is more durable and lasting than ordinary lamps, so you can reduce more costs in terms of replacing lamps.

Advantages of LED high bay lights

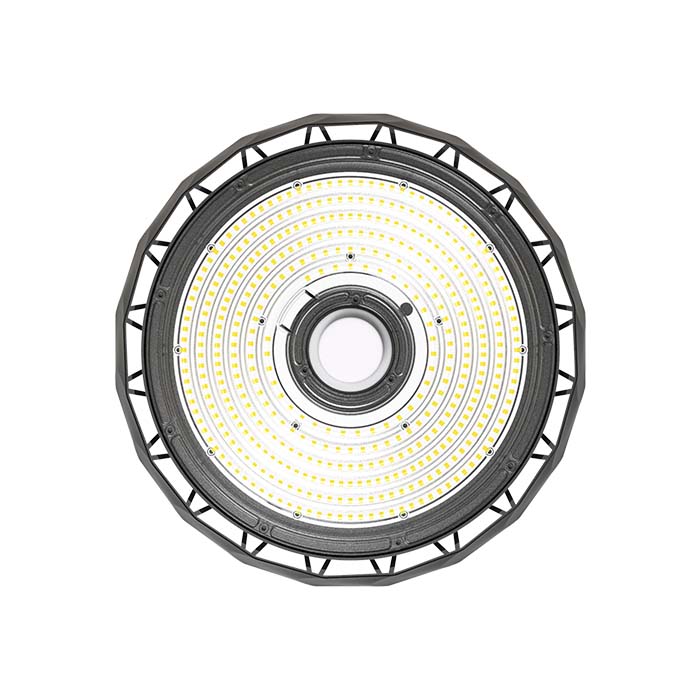

1. Ultra-high luminous efficiency, the industry’s ultra-high luminous efficiency of 150lm/W, using Philips high-brightness high-temperature resistant 3030 high-power lamp beads;

2. High redundant heat dissipation, low temperature and low light attenuation, high-end phase change radiator and affordable fin radiator are available;

3. High-reliability and long-life drive, extremely high reliability, the industry's higher lightning protection level of 12kV, and the drive's warranty for seven years;

4. Five-year warranty, triple redundancy of lamp beads, heat dissipation and driving;

5. It can be widely used in factories, workshops, warehouses, etc.;

6. Anti-corrosion in high temperature environment, special sealing and surface coating treatment;

7. A variety of installation methods, sitting type and boom type are available;

8. The transparent structure design is adopted to optimize the heat dissipation structure and extend the service life;

9. The angle is fixed to ensure that it will not change when used in a vibrating environment.

The performance optimization design of LED high bay light products is suitable for large-scale places with high requirements on brightness. High brightness and good color rendering. Precision pure aluminum radiator, with brand chip power supply, has the characteristics of anti-light decay, pure light color and anti-flicker. It is more energy-efficient than traditional metal halide lamps, and presents the actual color more realistically, making the visual sense more comfortable. However, it is necessary to pay attention to many details during installation, which will not only extend the service life of LED high bay lights, but also save a lot of costs.